A hard disk drive (HDD)[b] is a data storage device used for storing and retrieving digital information using rapidly rotating disks (platters) coated with magnetic material.[2] An HDD retains its data even when powered off. Data is read in a random-access manner, meaning individual blocks of data can be stored or retrieved in any order rather thansequentially. An HDD consists of one or more rigid ("hard") rapidly rotating disks (platters) with magnetic headsarranged on a moving actuator arm to read and write data to the surfaces.

Introduced by IBM in 1956,[3] HDDs became the dominant secondary storage device for general-purpose computers by the early 1960s. Continuously improved, HDDs have maintained this position into the modern era of servers andpersonal computers. More than 200 companies have produced HDD units, though most current units are manufactured by Seagate, Toshiba and Western Digital. Worldwide disk storage revenues were US $32 billion in 2013, down 3% from 2012.[4]

The primary characteristics of an HDD are its capacity and performance. Capacity is specified in unit prefixescorresponding to powers of 1000: a 1-terabyte (TB) drive has a capacity of 1,000 gigabytes (GB; where 1 gigabyte = 1 billion bytes). Typically, some of an HDD's capacity is unavailable to the user because it is used by the file system and the computer operating system, and possibly inbuilt redundancy for error correction and recovery. Performance is specified by the time required to move the heads to a track or cylinder (average access time) plus the time it takes for the desired sector to move under the head (average latency, which is a function of the physical rotational speed in revolutions per minute), and finally the speed at which the data is transmitted (data rate).

The two most common form factors for modern HDDs are 3.5-inch in desktop computers and 2.5-inch in laptops. HDDs are connected to systems by standard interface cables such as SATA (Serial ATA), USB or SAS (Serial attached SCSI) cables.

As of 2015, the primary competing technology for secondary storage is flash memory in the form of solid-state drives(SSDs). HDDs are the dominant medium for secondary storage due to advantages in price per unit of storage and recording capacity.[5][6] However, SSDs are replacing HDDs where speed, power consumption and durability are more important considerations.[7][8]

History

Main article: History of hard disk drives

| Parameter | Started with | Developed to | Improvement |

|---|---|---|---|

| Capacity (formatted) | 3.75 megabytes[9] | eight terabytes | two-million-to-one |

| Physical volume | 68 cubic feet (1.9 m3)[c][3] | 2.1 cubic inches(34 cc)[10] | 57,000-to-one |

| Weight | 2,000 pounds (910 kg)[3] | 2.2 ounces(62 g)[10] | 15,000-to-one |

| Average access time | about 600 milliseconds[3] | a few milliseconds | about 200-to-one |

| Price | US$9,200 per megabyte[11][dubious ] | < $0.05 per gigabyte by 2013[12] | 180-million-to-one |

| Areal density | 2,000 bits per square inch[13] | 826 gigabits per square inch in 2014[14] | > 400-million-to-one |

HDDs were introduced in 1956 as data storage for an IBM real-time transaction processing computer and were developed for use with general-purpose mainframe and minicomputers. The first IBM drive, the 350 RAMAC, was approximately the size of two refrigerators and stored five million six-bit characters (3.75 megabytes)[9] on a stack of 50 disks.

In 1962 IBM introduced the model 1311 disk drive, which was about the size of a washing machine and stored two million characters on a removable disk pack. Users could buy additional packs and interchange them as needed, much like reels ofmagnetic tape. Later models of removable pack drives, from IBM and others, became the norm in most computer installations and reached capacities of 300 megabytes by the early 1980s. Non-removable HDDs were called "fixed disk" drives.

Some high performance HDDs were manufactured with one head per track, e.g., IBM 2305so that no time was lost physically moving the heads to a track.[15] Known as Fixed-Head or Head-Per-Track disk drives they were very expensive and are no longer in production.[16]

In 1973, IBM introduced a new type of HDD codenamed "Winchester". Its primary distinguishing feature was that the disk heads were not withdrawn completely from the stack of disk platters when the drive was powered down. Instead, the heads were allowed to "land" on a special area of the disk surface upon spin-down, "taking off" again when the disk was later powered on. This greatly reduced the cost of the head actuator mechanism, but precluded removing just the disks from the drive as was done with the disk packs of the day. Instead, the first models of "Winchester technology" drives featured a removable disk module, which included both the disk pack and the head assembly, leaving the actuator motor in the drive upon removal. Later "Winchester" drives abandoned the removable media concept and returned to non-removable platters.

Like the first removable pack drive, the first "Winchester" drives used platters 14 inches (360 mm) in diameter. A few years later, designers were exploring the possibility that physically smaller platters might offer advantages. Drives with non-removable eight-inch platters appeared, and then drives that used a 51⁄4 in (130 mm) form factor (a mounting width equivalent to that used by contemporary floppy disk drives). The latter were primarily intended for the then-fledgling personal computer (PC) market.

As the 1980s began, HDDs were a rare and very expensive additional feature in PCs, but by the late 1980s their cost had been reduced to the point where they were standard on all but the cheapest computers.

Most HDDs in the early 1980s were sold to PC end users as an external, add-on subsystem. The subsystem was not sold under the drive manufacturer's name but under the subsystem manufacturer's name such as Corvus Systems and Tallgrass Technologies, or under the PC system manufacturer's name such as the Apple ProFile. The IBM PC/XT in 1983 included an internal 10 MB HDD, and soon thereafter internal HDDs proliferated on personal computers.

External HDDs remained popular for much longer on the Apple Macintosh. Every Mac made between 1986 and 1998 has a SCSI port on the back, making external expansion easy; also, "toaster" Compact Macs did not have easily accessible HDD bays (or, in the case of the Mac Plus, any hard drive bay at all), so on those models, external SCSI disks were the only reasonable option.

The 2011 Thailand floods damaged manufacturing plants, and impacted hard disk drive cost adversely in 2011-2013.[17]

Driven by ever increasing areal density since their invention, HDDs have continuously improved their characteristics; a few highlights are listed in the table above. At the same time, market application expanded from mainframe computers of the late 1950s to most mass storage applications including computers and consumer applications such as storage of entertainment content.

Technology

Magnetic recording

See also: Magnetic storage

An HDD records data by magnetizing a thin film of ferromagnetic material[d] on a disk. Sequential changes in the direction of magnetization represent binary data bits. The data is read from the disk by detecting the transitions in magnetization. User data is encoded using an encoding scheme, such as run-length limited encoding,[e] which determines how the data is represented by the magnetic transitions.

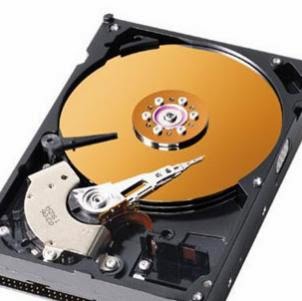

A typical HDD design consists of a spindle that holds flat circular disks, also called platters, which hold the recorded data. The platters are made from a non-magnetic material, usually aluminium alloy, glass, or ceramic, and are coated with a shallow layer of magnetic material typically 10–20 nm in depth, with an outer layer of carbon for protection.[19][20][21] For reference, a standard piece of copy paper is 0.07–0.18 millimetres (70,000–180,000 nm).[22]

The platters in contemporary HDDs are spun at speeds varying from 4,200 rpm in energy-efficient portable devices, to 15,000 rpm for high-performance servers.[24]The first HDDs spun at 1,200 rpm[3] and, for many years, 3,600 rpm was the norm.[25] As of December 2013, the platters in most consumer-grade HDDs spin at either 5,400 rpm or 7,200 rpm.

Information is written to and read from a platter as it rotates past devices called read-and-write heads that operate very close (often tens of nanometers) over the magnetic surface. The read-and-write head is used to detect and modify the magnetization of the material immediately under it.

In modern drives there is one head for each magnetic platter surface on the spindle, mounted on a common arm. An actuator arm (or access arm) moves the heads on an arc (roughly radially) across the platters as they spin, allowing each head to access almost the entire surface of the platter as it spins. The arm is moved using a voice coil actuator or in some older designs a stepper motor. Early hard disk drives wrote data at some constant bits per second, resulting in all tracks having the same amount of data per track but modern drives (since the 1990s) use zone bit recording—increasing the write speed from inner to outer zone and thereby storing more data per track in the outer zones.

In modern drives, the small size of the magnetic regions creates the danger that their magnetic state might be lost because of thermal effects, thermally induced magnetic instability which is commonly known as the "superparamagnetic limit." To counter this, the platters are coated with two parallel magnetic layers, separated by a 3-atom layer of the non-magnetic element ruthenium, and the two layers are magnetized in opposite orientation, thus reinforcing each other.[26] Another technology used to overcome thermal effects to allow greater recording densities is perpendicular recording, first shipped in 2005,[27] and as of 2007 the technology was used in many HDDs.[28][29][30]

Components

A typical HDD has two electric motors; a spindle motor that spins the disks and an actuator (motor) that positions the read/write head assembly across the spinning disks. The disk motor has an external rotor attached to the disks; the stator windings are fixed in place. Opposite the actuator at the end of the head support arm is the read-write head; thin printed-circuit cables connect the read-write heads to amplifier electronics mounted at the pivot of the actuator. The head support arm is very light, but also stiff; in modern drives, acceleration at the head reaches 550 g.

The actuator is a permanent magnet and moving coil motor that swings the heads to the desired position. A metal plate supports a squat neodymium-iron-boron (NIB) high-flux magnet. Beneath this plate is the moving coil, often referred to as the voice coil by analogy to the coil in loudspeakers, which is attached to the actuator hub, and beneath that is a second NIB magnet, mounted on the bottom plate of the motor (some drives only have one magnet).

The voice coil itself is shaped rather like an arrowhead, and made of doubly coated copper magnet wire. The inner layer is insulation, and the outer is thermoplastic, which bonds the coil together after it is wound on a form, making it self-supporting. The portions of the coil along the two sides of the arrowhead (which point to the actuator bearing center) interact with the magnetic field, developing a tangential force that rotates the actuator. Current flowing radially outward along one side of the arrowhead and radially inward on the other produces the tangential force. If the magnetic field were uniform, each side would generate opposing forces that would cancel each other out. Therefore the surface of the magnet is half N pole, half S pole, with the radial dividing line in the middle, causing the two sides of the coil to see opposite magnetic fields and produce forces that add instead of canceling. Currents along the top and bottom of the coil produce radial forces that do not rotate the head.

The HDD's electronics control the movement of the actuator and the rotation of the disk, and perform reads and writes on demand from the disk controller. Feedback of the drive electronics is accomplished by means of special segments of the disk dedicated to servo feedback. These are either complete concentric circles (in the case of dedicated servo technology), or segments interspersed with real data (in the case of embedded servo technology). The servo feedback optimizes the signal to noise ratio of the GMR sensors by adjusting the voice-coil of the actuated arm. The spinning of the disk also uses a servo motor. Modern disk firmware is capable of scheduling reads and writes efficiently on the platter surfaces and remapping sectors of the media which have failed.

Error rates and handling

Modern drives make extensive use of error correction codes (ECCs), particularly Reed–Solomon error correction. These techniques store extra bits, determined by mathematical formulas, for each block of data; the extra bits allow many errors to be corrected invisibly. The extra bits themselves take up space on the HDD, but allow higher recording densities to be employed without causing uncorrectable errors, resulting in much larger storage capacity.[31] For example, a typical 1 TB hard disk with 512-byte sectors provides additional capacity of about 93 GB for the ECC data.[32]

In the newest drives, as of 2009, low-density parity-check codes (LDPC) were supplanting Reed-Solomon; LDPC codes enable performance close to the Shannon Limit and thus provide the highest storage density available.[33]

Typical hard disk drives attempt to "remap" the data in a physical sector that is failing to a spare physical sector provided by the drive's "spare sector pool" (also called "reserve pool"),[34] while relying on the ECC to recover stored data while the amount of errors in a bad sector is still low enough. The S.M.A.R.T (Self-Monitoring, Analysis and Reporting Technology) feature counts the total number of errors in the entire HDD fixed by ECC (although not on all hard drives as the related S.M.A.R.T attributes "Hardware ECC Recovered" and "Soft ECC Correction" are not consistently supported), and the total number of performed sector remappings, as the occurrence of many such errors may predict an HDD failure.

The "No-ID Format", developed by IBM in the mid-1990s, contains information about which sectors are bad and where remapped sectors have been located.[35]

Only a tiny fraction of the detected errors ends up as not correctable. For example, specification for an enterprise SAS disk (a model from 2013) estimates this fraction to be one uncorrected error in every 1016 bits,[36] and another SAS enterprise disk from 2013 specifies similar error rates.[37] Another modern (as of 2013) enterprise SATA disk specifies an error rate of less than 10 non-recoverable read errors in every 1016 bits.[38] An enterprise disk with a Fibre Channel interface, which uses 520 byte sectors to support the Data Integrity Field standard to combat data corruption, specifies similar error rates in 2005.[39]

The worst type of errors are those that go unnoticed, and are not even detected by the disk firmware or the host operating system. These errors are known as silent data corruption, some of which may be caused by hard disk drive malfunctions.

Future development

HDD areal density's long term exponential growth has been similar to a 41% per year Moore's law rate; the rate was 60–100% per year beginning in the early 1990s and continuing until about 2005,[41][42] an increase which Gordon Moore (1997) called "flabbergasting" and he speculated that HDDs had "moved at least as fast as the semiconductor complexity."[43]However, the rate decreased dramatically around 2006 and, during 2011–2014, growth was in the annual range of 5–10%.[44] Disk cost per byte improved nearly -45% per year during 1990–2010, and slowed after 2010 due to the Thailand floods and difficulty in migrating from perpendicular recording to newer technologies.[45][46][47] Moore (2005) further observed that growth cannot continue forever.[48]

Increasing areal density corresponds to an ever decreasing bit cell size. In 2013 a production desktop 3 TByte HDD (4 platters) would have had an areal density of about 500 Gbit/in2 which would have amounted to a bit cell comprising about 18 magnetic grains (11 by 1.6 grains).[49] Since the mid-2000s areal density progress has increasingly been challenged by asuperparamagnetic trilemma involving grain size, grain magnetic strength and ability of the head to write.[50] In order to maintain acceptable signal to noise smaller grains are required; smaller grains may self-reverse (thermal instability) unless their magnetic strength is increased, but known write head materials are unable to generate a magnetic field sufficient to write the medium. Several new magnetic storage technologies are being developed to overcome or at least abate this trilemma and thereby maintain the competitiveness of HDDs with respect to products such as flash memory-based solid-state drives (SSDs).

One such technology, shingled magnetic recording (SMR), was introduced in 2013 by Seagate as "the first step to reaching a 20 TB HDD by 2020";[51] Starting from the 8 TB hard drives of 2015, the pace of advancement would be 20% per year. However, SMR comes with design complexities that may slow write performance.[52][53] Other new recording technologies that, as of 2015, still remain under development include heat-assisted magnetic recording (HAMR),[54][55]microwave-assisted magnetic recording (MAMR),[56] two-dimensional magnetic recording (TDMR),[49][57] bit-patterned recording (BPR),[58] and "current perpendicular to plane" giant magnetoresistance (CPP/GMR) heads.[5

Depending upon assumptions on feasibility and timing of these technologies, the median forecast by industry observers and analysts for 2016 and beyond for areal density growth is 20% per year with a range of 10% to 40%.[49][62][63][64][65] The ultimate limit for the BPR technology may be the superparamagnetic limit of a single particle that is estimated to be about two orders of magnitude higher than the 500 Gbits/in2 density represented by 2013 production desktop HDDs

.jpg)